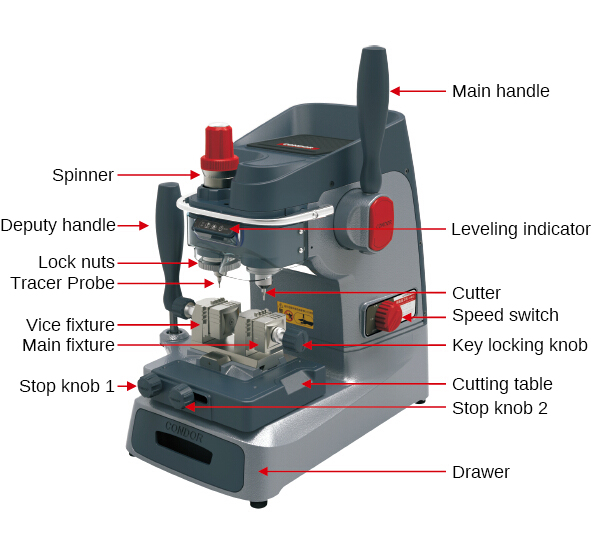

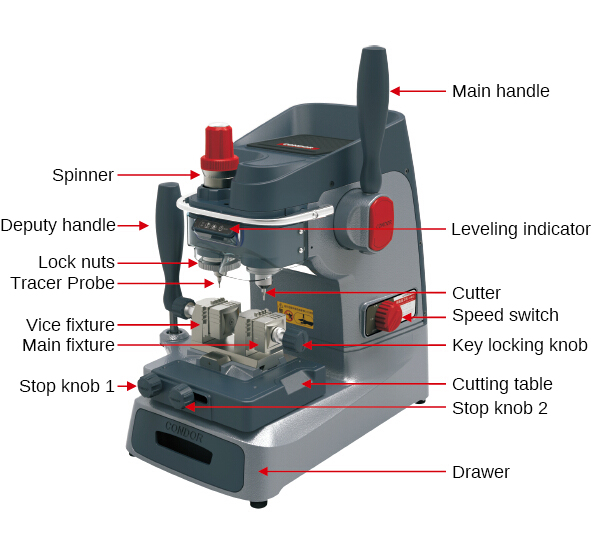

Product Description

Condor XC-002 is the ideal key machine to start cutting laser (single, double, four-track etc.) and dimple keys (Cisa, Brisant, Mul-T-Lock etc.). Easy to use and extremely precise, you will cover a wide range of automotive and household keys.

Xhorse Mechanical Key Cutting Machine CONDOR XC-002

Xhorse Condor XC-002 Highlights:

Precision-machined high-strength aluminum die-casting chassis

Convenient and practical ergonomics handle design

Patented rotating clamp design supports many different key types

Modular components for easy disassembly and maintenance

Renishaw line detection system, column cross guide rail

One-year warranty

Main Features:

1.Minimalism streamline design.

2.Ultra-strength aluminum alloy die casting with superior texture.

3.Convenient and practical ergonomics handle design.

4.Patented rotating clamp design suitable for multi key blanks and blades

5.Gross rolling guided bearing track ensures easy operation.

6.Modulated components for easy disassembly and maintenance.

7.DMG CNC Processing.

Condor XC-002 Advantages:

Ergonomic Design

CONDOR Mechanical Key Cutting Machine ergonomic design for customers After deep studying of user habits, achieved the best balance from optimal design and continuous improvement of all Aspects, such as Material, length, radian, Grip feeling, strength of control, feedback level, operation fluency. Excellent performance contributes to a veritable locksmith weapon.

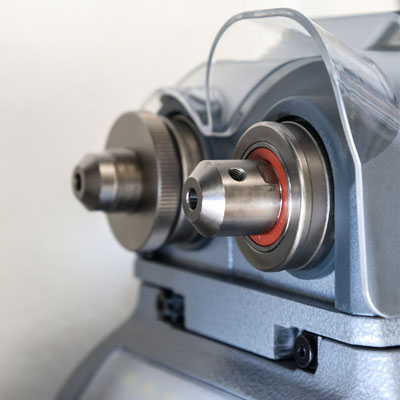

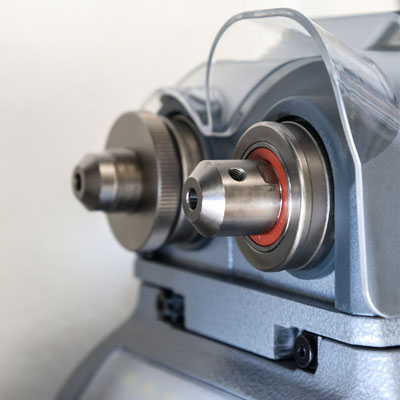

Superior Machine Components

CONDOR Mechanical Key Cutting Machine is composed by high leve machine components, ensuring the high reliability of the indicators key cutting fluency and accuracy. korea-made Bearing cage with high stability, cross railtested by British Renishaw online testing system, japan-made materials key cutter with special coating contribute to perfect cutting.

Humanized Function

CONDOR Mechanical Key Cutting Machine built-in height level adjustment indicator light, Spindle height fxed function and cutting table stop design, setting motor speed by manual and including double-ended probe, supports track, dimple, other special keys and more humanized functions.

Manufacture Process

CONDOR Mechanical Key Cutting Machine is aluminum-casting body, more reliable and stable. Mainly mechanical units manufactured by germany-made DMG CNC machine, ensures the accuracy of machine structure and for cutting keys

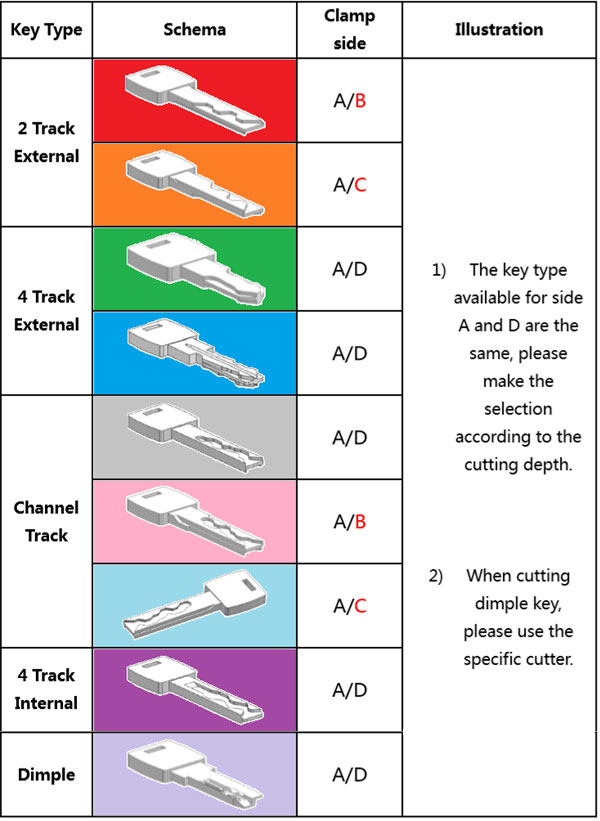

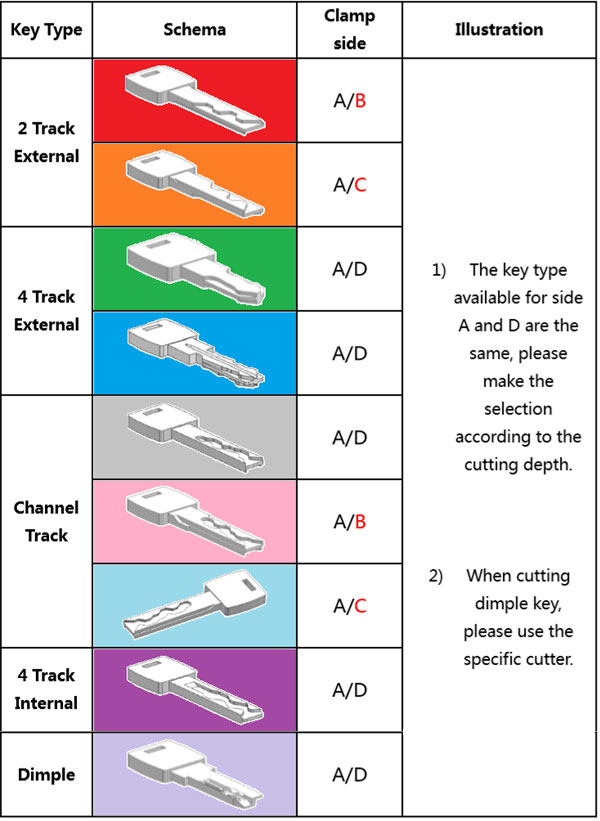

Clamp

CONDOR Mechanical Key Cutting Machine with independent researched and developed four in one clamp, a unique four-sided rotation design. Users can select different sides to work according to different key blanks. Easy and simple for cutting different keys.

Power/Motor Specification

CONDOR Mechanical Key Cutting Machine built-in super power 200 Watt motor with max speed 10000rpm, supports setting speed by manual, according to different key blank materials Ensure machine with high effcient work.

Technical Support

XHorse technical support team is professional and effcient, online technical support for free. one-year warranty and lifelong after-sale perfect service guarantee customers trouble free operation of machine. Customer feedback and suggestion are appreciated.

Condor XC-002 Specification:

| Input voltage |

220VAC |

| Input frequency |

50MHz |

| Consume |

200W |

| Package Dimensions |

L595xW550xH375mm |

| Machine Dimensions |

L298xW445xH525mm |

| Spindle Speeds |

8000-10000rpm |

| Noise Decibel |

77dB |

| Working Temperature |

0-50℃ |

| Humidity |

10-90% |

| Net Weight |

23Kg |

| Gross Weight |

28Kg |

Comparison Between Condor XC-002, XC-MINI and XC-007

Comparison Between Condor XC-002, XC-MINI and XC-007

| Xhorse Condor cutting machines |

Condor XC-002 |

Condor XC-MINI Plus |

Condor XP-007 |

| Image |

|

|

|

| Quality |

Made by Xhorse |

Made by Xhorse |

Made by Xhorse |

| Automatically/ Mechanically |

Mechanically/Manually |

Automatically |

Automatically |

| Lost key |

Not support |

Support |

Support |

| Touch screen |

No screen |

7" Capacitive |

Large screen |

| Cut key for car |

Yes |

Yes |

Yes |

| Cut house key |

Can cut a small part of house key |

No |

No |

| Internal software |

NO |

Yes |

Yes |

| Language |

It is mechanical, no specific language |

Portuguese/Spanish/French/Germany/Russian/

Czech/Arabic/Turkish/Dutch/Polish/Bulgarian/

Norway/Slovakia/Italian/English/Chinese (English is the default language,

after receive the machiche, send SN to seller for reset other language) |

English, Chinese |

| Stand-alone |

Yes, no need connect to computer |

Yes, no need connect to computer |

Yes, no need connec to computer |

| Input Voltage |

220VAC |

90V–264VAC |

AC110V/220V |

| Input Frequency |

50Hz |

47~63Hz |

47~63Hz |

| Consume |

200W |

200W |

220W |

| Packing Dimensions |

L595*W550*H375mm |

L450*W450*H350mm |

L460*W 520*H 620mm |

| Machine Dimensions |

L298*W445*H525mm |

L265*W362*H301mm |

L336*W407*H490mm |

| Display |

|

1024*600 |

800*480 |

| Spindle Speeds |

8000-10000rpm |

9000rpm |

12,000 rpm |

| USB |

|

USB2.0 |

USB2.0 |

| Working Temperature |

0~50℃ |

0~50℃ |

0~50℃ |

| Humidity |

10~90% |

10~90% |

10~90% |

| Net Weight |

23Kg |

18Kg |

31Kg |

| Gross Weight |

28Kg |

22.9Kg |

35Kg |

| Price |

$1199 free shipping |

$2,799 free shipping |

$2,970 free shipping |

| Warranty |

1 year |

3 years |

1 year |

CONDOR XC002 Detailed Pic:

Package Including:

Xhorse Mechanical Key Cutting Machine CONDOR XC-002

How to use Condor XC-002 key clamp?

How to Get Condor XC-002 Serial number?

How to Get Condor XC-002 Serial number?

When you bind condor with vvdi mb tool, it needs to provide two number of condor xc-002 (SN:MK******** NO********), please check from document as following pic, or on the main body of XC-002.

Autel Hot Items, 100% Genuine, EU/UK Ship Original Launch X-431 Best Seller, Up To 30% Off

Original Launch X-431 Best Seller, Up To 30% Off Any questions, please don't hesitate to contact us:Email: sales@CarDiagTool.co.ukSkype: cardiag.co.uk

Any questions, please don't hesitate to contact us:Email: sales@CarDiagTool.co.ukSkype: cardiag.co.ukWhatsapp:

+86 15002705698Scan QR Code to Order By Mobile Phone Shipping Method & Delivery:UK/EU Warehouse Shipping:

Shipping Method & Delivery:UK/EU Warehouse Shipping: 3-5 working days. Fast Delivery No Tax.

EU Check:

Ship from EUUK Check:

Ship from UKDHL Shipping: 5-7 working days, you need pay some tax to your customs. Usually we declare a lower price on DHL invoice to help with customs clearance. If your address belongs to remote area, customer will need to pay remote handling cost. Please remember to leave message if you have any special requirement.

Yanwen Express: 10-15 working days. No Tax or remote cost for European Countries.

Yodel/Royal Mail: Just for United Kingdom. No Tax, and the delivery is about 7-10 days.

Standard Post: The delivery is about 15-20 days, no tax. Order under $150 normally with default shipping Standard Post, customers can tick for Express Shipping Service to ship by DHL.

Warranty Item:Almost all item has one year warranty.

We also offer free fix to almost item we sold within one year, free repair. Man-made damage need pay.

We not offer warranty on keys,cables,adapter,online sent software ,please notice it.

Software Download

How to use Condor XC-002 Key Cutting Machine?

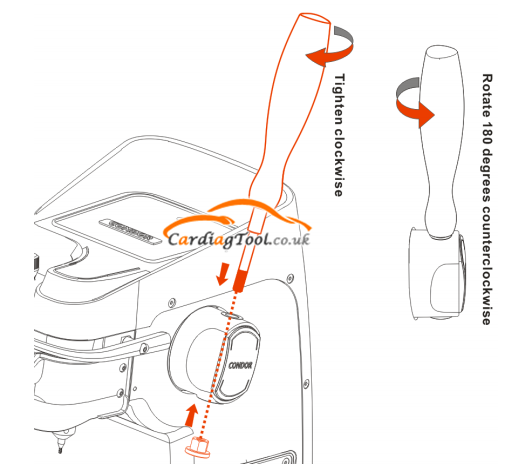

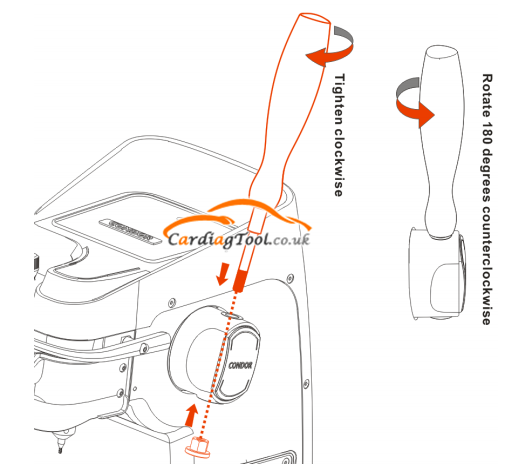

1.INSTALLING MAIN HANDLE

1) Insert the bottom of main handle into installing hole, which is by the right side of the machine body. Then cover the screw cap and rotate the handle clockwise until tightened.

2) If fully tightened, the main handle should be fix at a certain position and unable to move up or down.

3) If rotate the handle 180 degrees counterclockwise, the height of tracer and cutter can be changed freely.

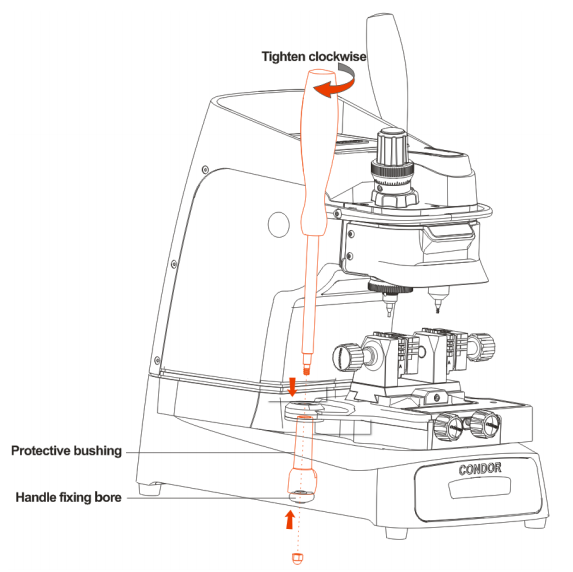

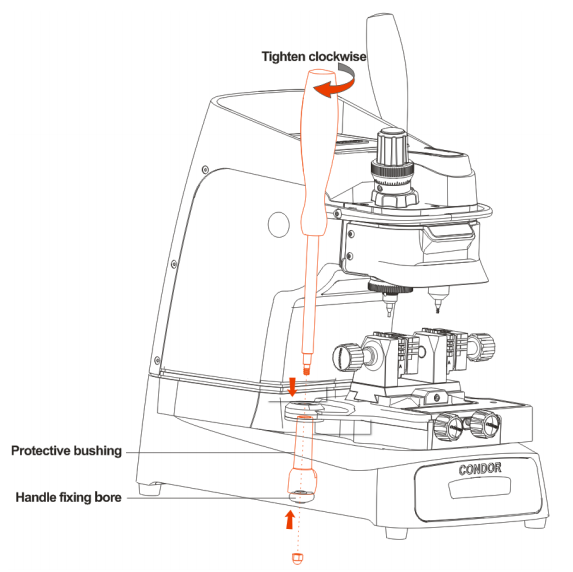

2 INSTALLING SUB-HANDLE

4) Insert the bottom of sub-handle into the installing hole, which is by the left side of the machine body. Put on the protective bushing and then plug in the lower bearing bore to avoid moving. Cover the screw cap and rotate the handle clockwise until tightened.

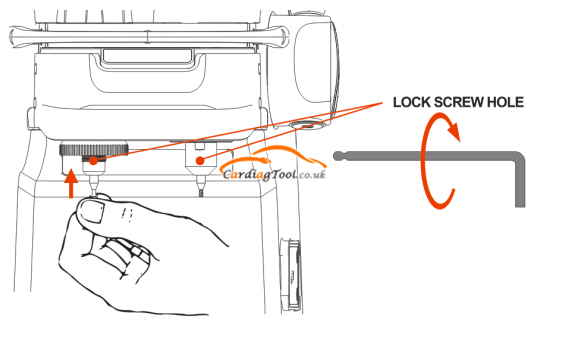

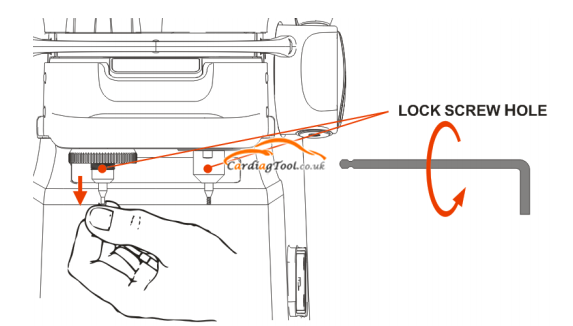

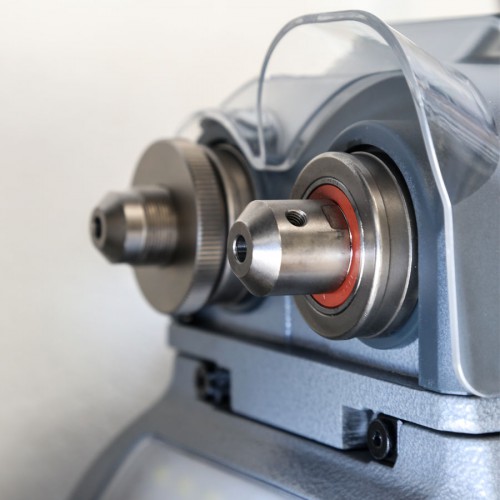

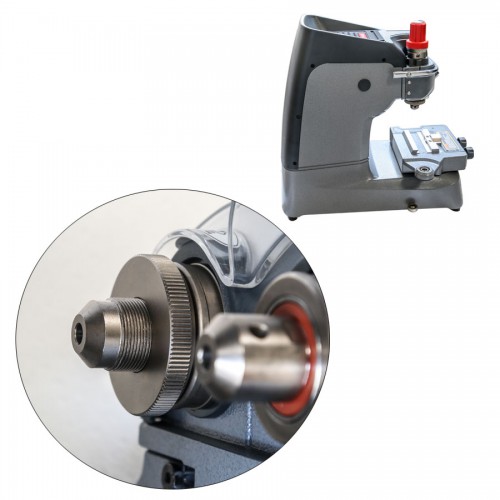

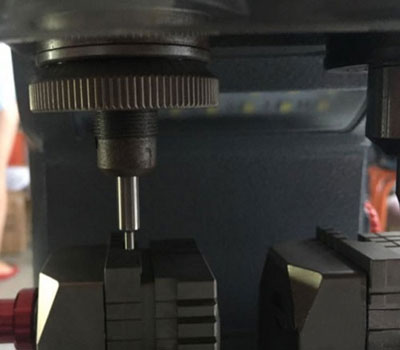

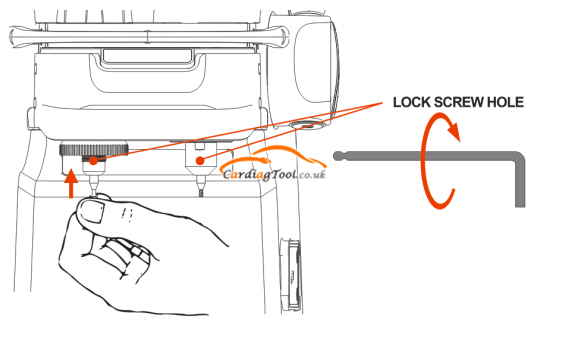

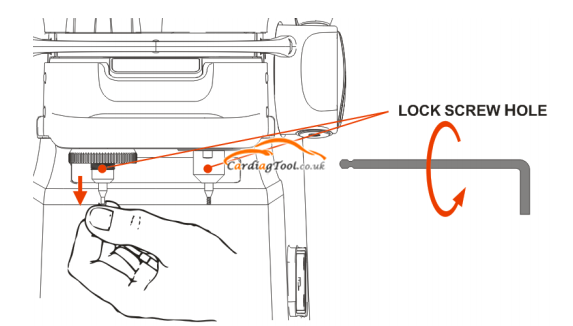

3.INSTALLING AND REMOVING PROBE/CUTTER

1) The left one is tracer and the right one is cutter. Put the tracer and cutter into the hole and to the top limit position. Then use 2.5mm Allen wrench to turn the lock screw clockwise respectively till the tracer and cutter are both tightened.

NOTE: When using 1.5mm cutter and 2.5mm cutter, tracer and cutter must select the top with the same diameter for processing.

2) Insert the wrench into the hole, turn the lock screw counterclockwise, and then remove trace and cutter.

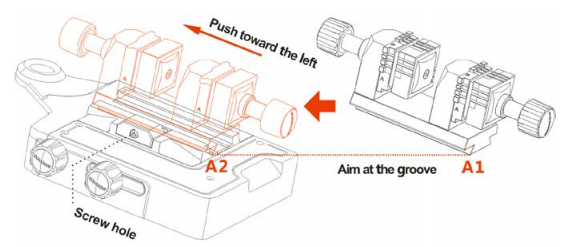

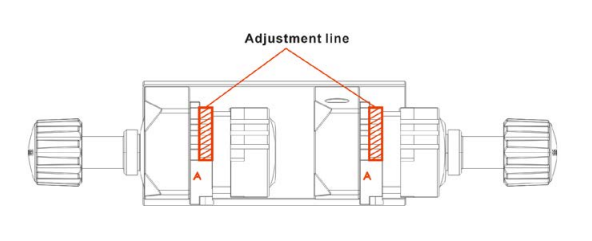

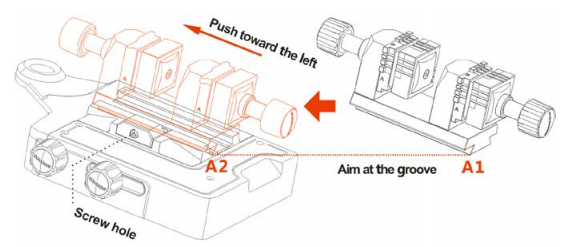

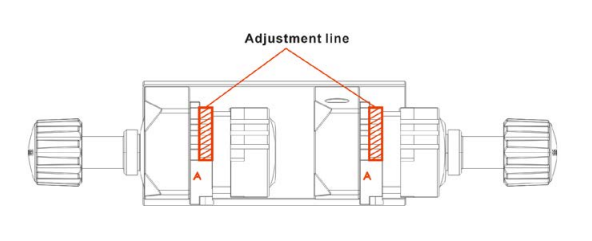

4. CLAMP INSTALLATION

Aim the bump (A1: underneath the clamp) at the cutting bench’s groove (A2), push toward the left until A1 and A2 (shown above) are fully overlapped. Then use 4mm Allen wrench to tighten the screw

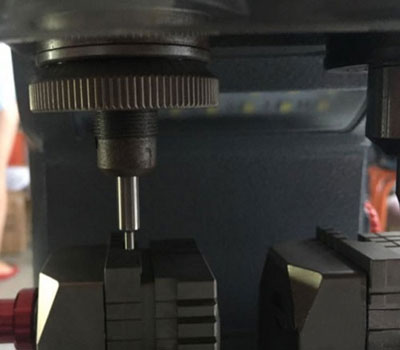

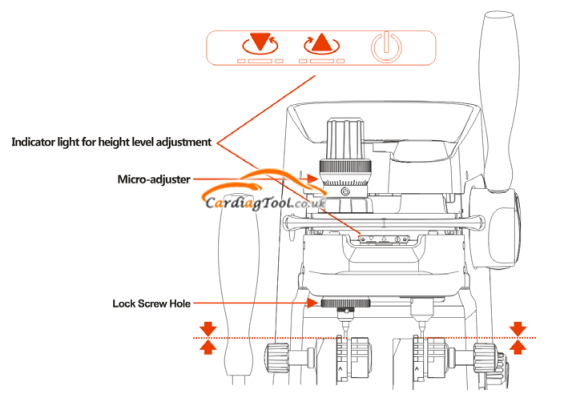

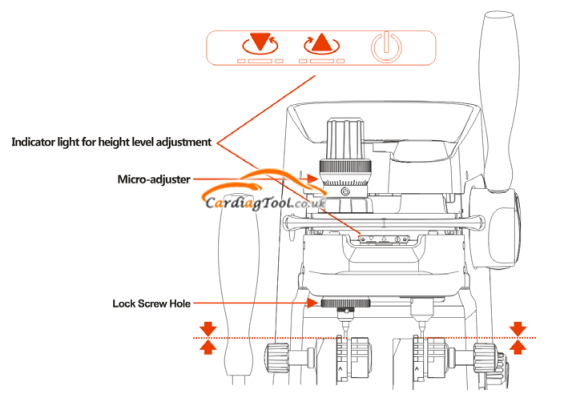

5. PROBE/CUTTER HEIGHT LEVEL ADJUSTMENT

1) When the installation finished, push the main handle. If the tracer is higher than cutter, the indicator light on the left will turn on.

2) If the tracer is lower than cutter, the indicator light on the right will turn on.

3) According to the signal of indicator light, rotate the Micro-adjuster until tracer and cutter’s tops have both touched the clamp. In other words, they are at the same height. Then two indicator lights will on, adjustment finished.

NOTE:During the height level adjustment, main clamp and sub-clamp must at the same side.

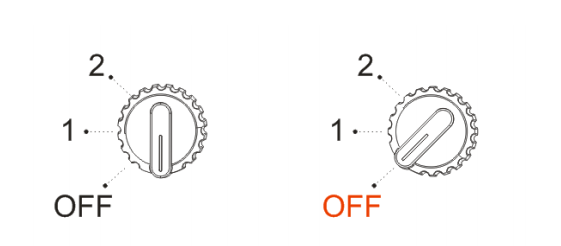

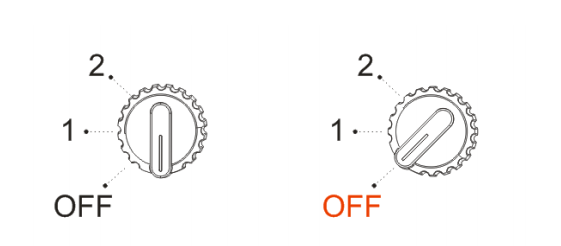

6. ROTATION SPEED ADJUSTMENT

Rotation adjustment knob locates at the right side of the machine. There are two gears to control the rotating speed of motor.

1) When the adjuster is at the neutral gear, motor stays at Turnoff mode; when it points to OFF, the light will be on, means the machine is ready to work.

2) When the adjuster points to 1, the motor rotates at a low speed, about 6000rpm; when it points to 2, the rotation speed is higher, about 8000rpm.

![[EU/UK Ship] Xhorse XCMN06EN 2.0mm Milling Cutter For Condor XC-Mini Plus/Plus II/XC-002 and Dolphin XP005/XP005L](/upload/pro-sm/22052616536159584103.jpg)

![[EU/UK Ship] Xhorse XCMN07EN 2.5mm Milling Cutter for Condor XC-Mini Plus/Plus II/XC-002 and Dolphin XP005/XP005L/XP007](/upload/pro-sm/22052616536164313777.jpg)

![[EU/UK Ship] Xhorse XCMN05EN 1.5mm Milling Cutter For Condor XC-Mini Plus/Plus II/XC-002 and Dolphin XP005/XP005L/XP007](/upload/pro-sm/22052616536152878758.jpg)